Automatic localization of products with cameras

Why do you need to localize products?

All machines at Promation are custom-made and have diverse functionalities.

- The one cobot can check if certain screws are present. Or even tighten them.

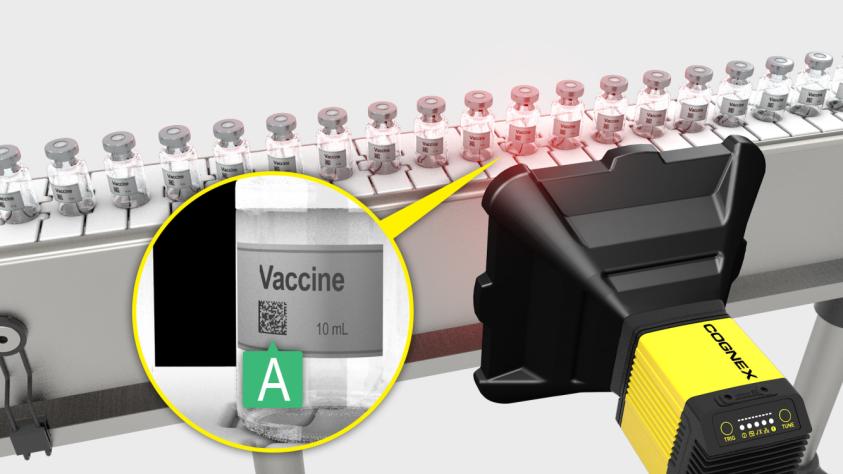

- The other cobot looks for products on a conveyor belt so it can package them.

- Yet another can pick up and move a cookie, bottle or bowl.

For all of those tasks, the robot must first be able to locate the products. Otherwise, the robot cannot do what you expect it to do. We do that using cameras, software and the control box for your robot.

Localization of products for control

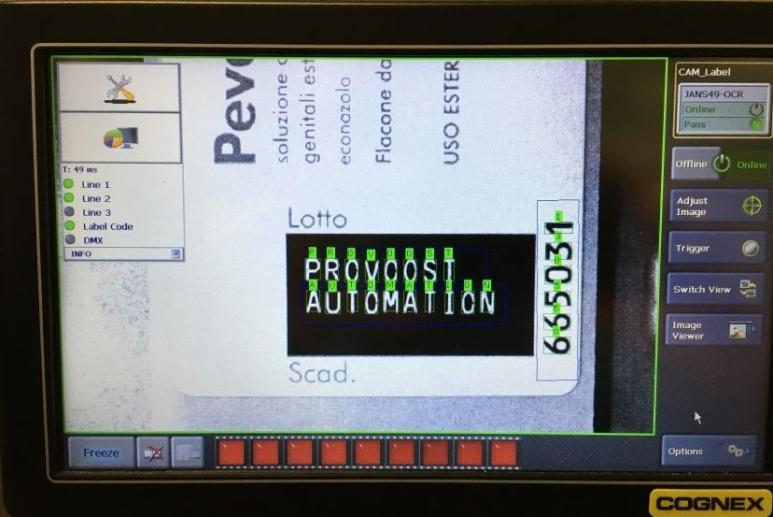

In modern production processes, vision systems are often used to control printed data and packaging.

In data control, the camera focuses on products passing by on the conveyor belt, automatically reading and verifying printed information.

In packaging control, the system takes a picture of the packaging. This image is then analysed based on predefined or learned characteristics, followed by an automatic assessment.

Other expertise within vision systems

Control printed data

The camera detects presence and correctness of printed, mandatory data.

Control of packaging

Check for codes, data, damages, errors, numbers, discrepancies and more.

Machine Vision

The umbrella term for vision systems. Locating, monitoring, measuring ...

ID Reading/barcode scanning

Cognex scanners that can read and interpret barcode data.

Creating the future together.

Interested in optimizing your production process with us?

Make a no-obligation appointment to discuss your needs and expectations. The experts at Promation will always provide you with honest advice.